If you cannot find the solution for your problem in the FAQ, please use the form below to post your question.

We’re now offering paid priority support through Fiverr.

- Installing Simple Data Logger

- License questions

- Using Simple Data Logger

- Asking for help

1. Installing Simple Data Logger

Installing SDL on a computer not connected to the internet

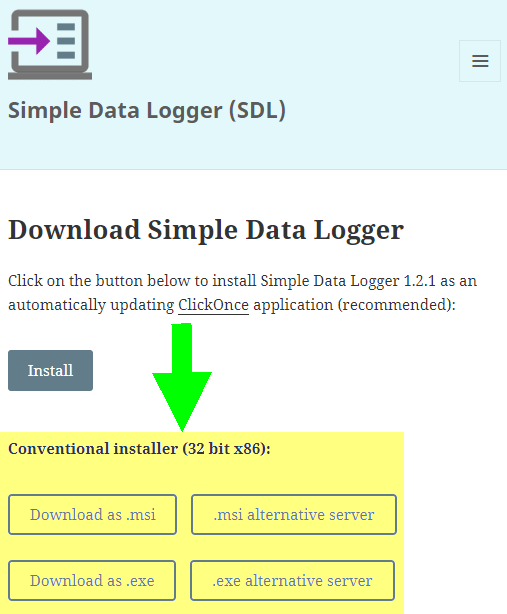

Simple Data Logger can be installed on computers that are not connected to the internet. On the Download page, choose one of the conventional installers (32 bit x86):

Please note that .NET Framework 4.7 or later must be installed on the computer.

When trying to install the ClickOnce version of SDL, you receive an error message that says that the “administrator has blocked this application because it potentially poses a security risk to your computer”

This is caused by the ClickOnce trust prompt configuration of your operation system. If you have administrator privileges, follow the instructions in this article to set the value of the “Internet” registry subkey to “Enabled” or “AuthenticodeRequired”.

You can also use our free TrustPrompt tool to configure this setting without having to edit the registry yourself.

Finally, you can also use the .msi or .exe installer available on the download page as an alterative to the recommended ClickOnce installer.

2. License questions

Please consult our License FAQ.

3. Using Simple Data Logger

No data is shown in the event log or written to the CSV file

If you believe that your device has sent data and that it should have been received by SDL, please press the stop button and follow the instructions below that apply to your situation. First, however, got to the settings tab and make sure that “show received data” is checked.

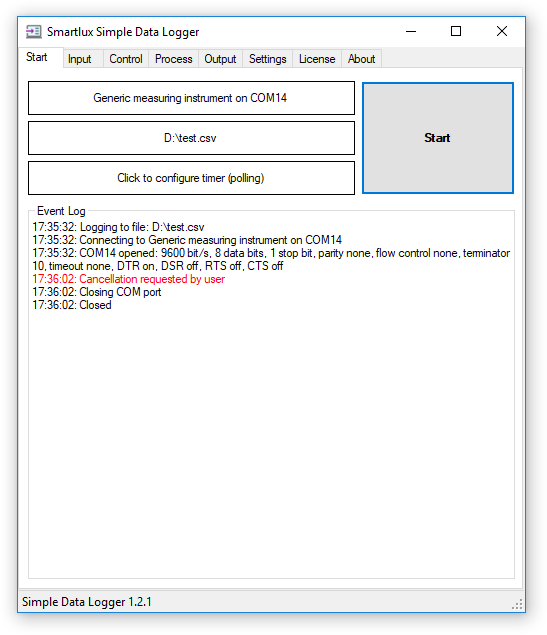

Case 1: No data or error message is shown in the event log (even after pressing the stop button)

This means that SDL has not received any data from your device. The four possible causes are described below.

- Your device is not sending any data. Refer to the manual to confirm that:

- Data transmission is enabled.

- Your device is set to the correct data transmission mode.

- There are no impediments for data to be sent. Examples: a) Many scales and balances are configured to send the weight only if or when it is stable. b) Legal for trade scales will usually not send values below the minimum weight.

If the user manual does not contain useful information, contact the equipment manufacturer or the dealer who sold the device to you. To prevent them from attributing the problem to our software, we recommend that you test communication with another application as described in point four below.

- The settings in the input tab in SDL do not match the settings of your device. This is a very common cause when using a COM port. For data transmission to succeed, the following conditions have to be fulfilled:

- You have to select the correct COM port. If you can choose from multiple ports, keep in mind that the fact that SDL can open a port does not mean that your device is actually connected to this port.

- All interface parameters (bits/s a.k.a. baud rate, data bits, stop bits, parity, flow control or DTR/RTS flags) have to match the settings of your device. If you’re using one of the “generic” profiles, it is very likely that you will have to change some of the interface parameters.

Please refer to the manual of your device to find its default interface parameters, then confirm that these are the actual settings used by your device. Most scales and balances will let you view or change the interface parameters through their menu.

If you’re using a pre-defined device profile in SDL (anything other than the “generic” profiles) and believe that our settings are not correct, please leave a comment. Please keep in mind that some manufacturers do unfortunately change the default interface parameters for their devices from time to time.

- There is something wrong with the connection between your device and your PC. Examples:

- Incompatible serial cables: Some devices require straight 1:1 cables, others need null modem cables while some unfortunately need special custom cables. The fact that you can physically connect a cable to your PC and device means nothing in terms of internal wiring and does not guarantee that data can be transmitted.

- If you’re not using a serial cable but are instead directly connecting a USB converter to the RS-232 port of your scale, the issue described above still exists! The pin assignment on most converters is identical to built-in RS-232 ports on a PC. However, some converters already provide null modem functionality.

- Connectors that are not plugged in all the way.

- RS-232 to USB converters that are recognized as human interface devices (HID) instead of virtual COM ports (VCP). SDL only works with VCP.

- You’ve found a bug in SDL. First of all, please make sure that you’re using the most recent version of SDL (compare the version number in the about tab with the changelog or the download page). Then, test the communication with your device with a different software. For connections using a COM port, you can use Termite or hTerm. For TCP/IP connections, try using PuTTY in “raw TCP” mode.

If you cannot receive any data from your device in these applications either, then then issue is not caused by SDL! Although we would very much like to help you, please understand that it is very difficult and time consuming for us to diagnose problems with your device, configuration or connection remotely. How would we, for instance, know if you’re using the correct serial cable? As mentioned above, consider contacting the equipment manufacturer or your dealer for support.

If you prefer that we try to help you, please pay for support from from us through Fiverr (STANDARD package).

Should you still choose to ask us to help you for free, please observe the guidelines posted below.

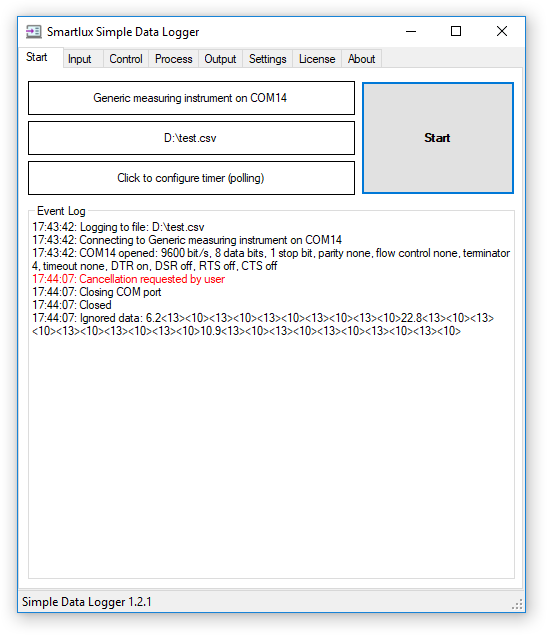

Case 2: An “ignored data” message is shown after pressing the stop button

If an “ignored data” message followed by human-readable data sent from your device appears in the event log, this means that the terminator in the input tab is not configured correctly.

In the screenshot above, the terminator was set to ASCII code 4, which does not appear in the data sent by the scale. The correct terminator would have been 10 (line feed). If you cannot determine the terminator, try using a timeout instead.

If the ignored data does not seem to make any sense (e.g. “: <0><24>?<24>??<30>03`<30>030<30>030<30>030<30>03?”), then one or more of the following interface parameters are wrong: bit/s, data bits or parity. It is also possible that your device is not able to send data in human-readable ASCII format. In this case, it can unfortunately not be used with SDL.

You can see data in the event log, but it’s not written to the file

- Make sure you’ve pressed the stop button to flush all data to the file.

- Confirm that the data shown in the event log is in ASCII format (i.e. you can read the data and don’t just see lots of non-printable characters shown in <brackets>).

SDL captures the wrong data

If you’ve selected a measuring instruments in the device tab, SDL will usually capture the first (decimal) number in each line. If this is not the measurement value you want, please try changing the output of your device. You can also customize the regular expression used by SDL to capture the data you want.

When polling the weight, an Ohaus scale replies with “ES”

Some Ohaus scale do not support the “IP” (immediate print) command. Try using the “P” (print) command instead.

4. Asking for help

Please observe the following points so that we can help you as fast as possible:

- Please indicate the manufacturer and exact type/model of your device. Bad examples: “a scale” or “an Ohaus scale”. Good example: “an Ohaus STX421 scale”.

- Please describe the problem precisely. “It does not work as expected” is far less helpful than “when I press the print button, only numbers in brackets show up in the event log in SDL (see attachment)”.

- Mention if you’ve tried any of the solutions or steps from the FAQ above. Example: “I tried sending the weight from my scale to the HTerm terminal software, but it also doesn’t show anything”.

- Attach a screenshot of the event log.

- Send us the user manual for your device if it’s not freely available on the internet.

- If we’ve successfully solved your problem, please confirm that the solution worked. This is important for other users with the same issue and it’s also a nice thing to do, particularly if we helped you solve a problem that was not caused by our software.

Hello

When I click stop to start the measurement, it says:

COM4 opened: 4800 bit/s, 8 data bits, 1 stop bit, parity none, flow control none, terminator 10, timeout none, DTR on, DSR on, RTS off, CTS on

but there is no data. I see that in the manula CTS and DSR are off. Where can I turn them off?

Thank you and best regards

CTS and DSR are controlled by the connected device and cannot be changed directly by our software. If CTS and DSR are on, this is usually a good sign and shows that your device is connected to your PC (the exact meaning of these signals differs from device to device).

Have you looked at other possible causes as described here? https://www.smartlux.com/sdl/faq-support/#no-data

Having trouble getting a Sartorius Quintix6102-1S data into the Simple Data Logger – any troubleshooting help on this would be appreciated. Just want to log weight and time.

Great software !

Congratulations.

Remy

I have the Port open, but there is no data being logged

Hi Hallie, please see the possible causes listed here: https://www.smartlux.com/sdl/faq-support/#no-data

SEAKS3011D Counting Scale by Fristaden Lab

When I try to select a port, it does not recognize that I have one. I click ¨refresh¨ but still nothing happens. I went to my Device Manager in my computer and tried to find the ¨ports¨ it does not even come up with a port for USB or COM. But rather it recognizes my plug in under the Other Devices tab as USB2.0 ser! How do I get it to recognize my port?

As the scale only has an RS-232 port, you’re probably using an RS-232 to USB adapter? If yes, please install the driver provided by the manufacturer. The adapter has to appear under “Ports (LPT & COM)” in the device manager, otherwise, no software will be able to use it.

When you mean the driver provided by the manufacturer, do you mean this XCOM V2.2 Software? I have attached a picture below.

No, I’m not sure what that is. How did you connect the scale to your PC? Are you using an RS-232-to-USB adapter cable? That cable should have a driver which will make it appear under “Ports (LPT & COM)” and in Simple Data Logger.

This is the cable I am using. I believe it is a VGA to USB adapter, however, I am not sure. I connected it with another VGA cable, because the blue piece (shown in pic) was only female and I need a male. Is that okay if I connected the two cables like that? Also, that is my problem, I do not appear to have a Ports(LPT & COM) under my desktop. How do I get that?

Thank you for the photo, the blue cable is actually an RS-232-to-USB adapter cable (the RS-232 DSub9 interface looks similar to VGA). You need the driver for this cable so that it is recognized as a COM port. If you can find out the manufacturer, the driver should be available on their website.

So Stephan, you are saying that I have tan RS-232-to-USB adapter cable, but I need the RS-232 DSub9? If so, I looked in the manual of the scale I am using and it says to “use an RS232 compatible cable to connect the balance to a printer via the RS232 connection port.” Below I have attached a picture. Thank you so much for the help and fast replies, I really appreciate it!

Sorry if this is confusing, but first you need a driver for the RS-232-to-USB adapter cable which you already have. Right now it is not being recognized correctly by Windows when plugged in on your PC (because the driver is missing). With the driver, it will be recognized as a COM port (and not as “other devices”).

Do you know the brand or manufacturer of the RS-232-to-USB adapter cable?

Oh that makes more sense! Unfortunately, I do not know the brand/manufacturer of the RS232 to USB cable. I just pulled it out of a random box at my work, because it had the USB adapter I needed. It has the number 340 on it if that helps?

“340” may stand for the CH340 chipset made by WCH. You can find the driver here: http://www.wch-ic.com/downloads/CH341SER_ZIP.html

Please run setup.exe after unzipping the file. If this is the correct driver, the RS232-to-USB cable should appear as a COM port.

Hello, for know am using the free version before buying the licence and a have some trouble when pushing the start command.

it says access is denied to save data in the CSV file that I created and that I have chosen to be the file where my data will be saved.

Plz see the attached picture of erreur a have sent.

Hello, for know am using the free version before buying the licence and a have some trouble when pushing the start command.

it says access is denied to save data in the CSV file that I created and that I have chosen to be the file where my data will be saved.

PLZ see the attached image am sending.

Thank you.

Your system does not allow SDL to access the file. Please try saving to a different directory or try running SDL as an administrator.

BTW you don’t have to create a CSV file externally, you can simply enter a (non-existing) file name in the dialogue in SDL and it will create the file for you.

Hallo,

is it possible to change the sampling frequency ?

By default, SDL records every value sent by the connected measuring device and the sample frequency is therefore determined by the device, not by SDL. Please consult the manual of your device to see if and how the frequency can be changed. Most scales and balances send 5 to 20 values per second.

If you’re using the polling function to request a measuring value from a device which supports this functionality, the frequency can be influenced by changing the Timer or Delay: https://www.smartlux.com/sdl/documentation/#polling

We are trialing a Proprietary Torque Tester communicating to the SDL Plus software. It has capabilities of sending a negative number. Please see attached or below as the first number is positive and the second is negative.

10:07:05: 6.4\- 6.7

I have only removed the ‘\’ and ‘-‘ to make the report look good.

How can I make the report show a 6.4 and a -6.7?

Customize Device .NET Framework?

Thanks in advance.

I have six scales on a single computer that I wish to capture data to files. Does your program allow for multiple scales?

Hi Andrew,

Simple Data Logger can only connect to one singe scale. We’re working on a new software with the ability to connect to multiple devices, it will be available in the first quarter of 2021.

Sorry if this is a general Windows question but can the file name include something like (%d%m%Y) to cause a new file to be automatically created each day? (Since the current date would be part of the name.)

Equipment is a homemade (PicAXE based) data taker for solar flare detection and LibraOffice will import the file every few minutes for posting to my web page using IrfanView. Hopefully I can tell LibraOffice to open a file with the current date embedded in the name in the same way.

Hi Charles, many thanks for your suggestion. I’ve included it in the list of feature requests and it is currently scheduled for version 1.6 (October).

Hi Guys

I like the software. I have a US solid USS-DBS46-3 I’m a bit confused with the settings. The manual states 10 bits 0 as a start bit, 1 as stop bit 8digits ASCII no parity.. it doesn’t want to play. It should communicate when the values is stable or a setting is changed But no dice.

I’ve not heard of this brand before, but I’ve found a somewhat hilariously confusing manual online. Please try the following settings for the “connection orifice” (COM port):

– Bits/s: 1200

– Data bits: 8

– Stop bits: 1

– Parity: None

– Terminator: Either 13 or 10, can’t tell from the manual, please try both.

The data format looks fine and should work with the “Generic measuring instrument” profile.

For testing purposes, try setting your scale to “continuous output” (if available) so that you can easily see if data is received.

If that doesn’t work, please ensure you’re using the correct cable. According to the manual, this scale seems to require a null modem cable (a.k.a) crossed cable. If you’re connecting it directly to a USB converter, you’ll most likely need a null modem adapter.

Please let us know if this works.

Hello,

I downloaded your trial version and plan to purchase your product for use at our fish hatchery.

I have a question regarding the output settings. In testing the software with this scale:

Ohaus Adventurer Pro AV812, the output displays several lines of unnecessary data. I would simply like to have a list of weights by date and time. The output includes a “1”, a number identifying the scale “1203130552” and three blank lines. I have read your documentation, but cannot find a solution. Attached is an image from my Test CSV file.

Thanks, Chip Blair

Hi Chip,

Thank you for your question! Many Ohaus balances send a lot of information like the balance ID, type, gross/net/tare weight, etc. There are two ways to fix this:

1. Recommended: Your scale can be configured to send only the weight (even though this is not explained at all in the manual). In the “Print” menu of your Adventurer Pro, you’ll find a “Num Only” entry. Please change this setting to “on”.

2. As an alternative, you can instruct SDL to ignore the values you don’t want. Go to the Input tab and click on the Customize button, then replace the regular expression with this one:

Net:\s*([-+]?\s*[0-9]*\.?[0-9]+)

This will capture only the net weight, but won’t remove all blank lines. You can try to use the Combine setting in the Process tab to transform them to columns.

Please let us know if you have further questions.

Hello,

I am currently attempting some data acquisition, and your software looks like something that would work very well for my application. I just wanted to ask a few questions before I bought a license. First, I wanted to confirm that that I would be able to use this software to create a timestamped table of measurements (for instance 1 measurement/second for 3 minutes). Second, I am on a relatively strict budget and was wondering if you could give me an estimate of how much a license would cost as I can’t seem to find it anywhere. Finally, I do not currently have a scale that would communicate with the software. Is there one particular scale (with at least a 150 lb max) that you would recommend? Maybe something that works better with your software than others?

Thank you for your time

Hi Neil, thanks for reaching out.

This software seems very cool, but I really can’t get it to work on my Radwag WLC 10/2A scale. I have tried to follow the instructions given here on your website, but can seem to get the scale to log data to a CSV file (nothing is written to the file, nor in the prompt/screen of SDL)

Really hope that you can help me get things up and working!

Which connection are you using with your Radwag scale (USB/RS-232/Ethernet)? For USB and RS-232 connections, the default settings defined for the “generic measuring instrument” correspond to the Radwag default settings.

If SDL does not receive any data, it is most likely a configuration issue with the scale itself. Please have a look at the “Peripheral Devices” section in the user manual. It seems that you have to select a port to which the computer is connected.

Really like the software. I am using it on an Ohaus Defender scale through RS232 to USB. Is it possible to hook up more than one scale? Would I need to open another instance of the program or would it cram the data from both scales into one file if the USBs were plugged into a hub?

SDL can currently only record the data from one scale. In your case, you would have two virtual COM ports and you can only select one of them in SDL. As you wrote, you could open another instance to connect to a second scale.

Thank you very much! Would you recommend a powered USB hub or is that not needed?

Not needed in my experience. Two converters on a passive hub could draw up to 200 mA each (if no other device is connected to the hub). For comparison, the FTDI US232R-10 converters we use have a maximum current of 50 mA.

Okay, much appreciated!

We are using EPB-10K (https://scaleman.com/epb-10k-10000g-x-0-1g.html – Manual link provided). This scale does not respond to prompts. It does have “Stablilized,” “Continuous,” and “Manual” modes, but the manual requires the Print key to be pressed.

We need to record data at desired intervals, but not all of the data provided by Continuous mode. We ask that you provide a “Data Recording Timer” function on the Output tab.

A filtering function is now available in version 1.4.0: https://www.smartlux.com/sdl/documentation/#filtering

Is there any commandline that would allow me to start the task automatically so the Start button can be automated. That combined with the feature to stop after a defined time that is already available would allow the task to run unattended for defined periods. Alternatively is there a keyboard combination the Start and Stop buttons react to that an automation script could trigger

There will be an option to start data acquisition automatically when the program is started in the next release (scheduled for next week).

We are having trouble getting the SDL software to display any values from our METTLER TOLEDO ABS135-S/FACT scale. We’ve confirmed that the correct parameters are the same for the scale and the software, but when we start the process nothing is displayed. However, when we press enter while running the process we see a lot of ‘?’ appear.

Please try configuring your scale as follows:

12 Peripheral Unit: HoSt

13 Send Format: SICS

14 Send mode: S. Stb

15 Baud rate: bd 9600

16 Bit/Parity: 8b-no

17 Handshake: HS Soft

In SDL, set the device to “Mettler Toledo (MT-SIS)” and press “set default parameters for device”.

You can then transfer the (stable) weight by briefly pressing the Cal/Menu button. If you would like to transfer the weight continuously, set “14 Send mode” to “S. Cont”.

In SDL Plus, you can also request the weight from the scale:

https://www.smartlux.com/sdl/documentation/#polling

Is it possible to record data at variable time frequency. For e.g can we record data every 5 seconds for first 5 minutes and afterwards record data every 1minute.

I’m sorry but this is not currently possible. We’ll introduce a “Pro” version of SDL soon which will be able to run user-defined scripts for (almost) unlimited flexibility.

Thank you for the response.

Hi,

I started using SDL plus version. I want o record data every 5 seconds. I used polling with a timer of 5000 ms. However, I am still recording data at the default frequency. I have attached the image of input parameters I used in control menu.

Kindly suggest.

Hi, most likely your measuring instrument is set to transfer data continuously. Please consult its manual to change the mode so that it only sends data after receiving a command from SDL (often called “command mode”). If you need further assistance, please let us know which measuring instrument you’re using. Thank you!

I am using Acculab AL 104.

I would appreciate any further suggestions.

Please try setting your scale’s print configuration to

“6 1 1 Manual with print key without stability” or

“6 1 2 Manual with print key at stability”.

Hi Stephan,

I tried implementing your suggestions but both manual mode doesn’t even provide any data. Autoprint provides correct data continuously when I use timer but I require data only at specific interval. However with delay function, the program only takes in the first weight it receives and does not update. Even when it does, it goes through a long time lag to display the data in the log. Please find the pictures regarding the input and polling configuration in the attachment. Thanks.

Please try the following:

1. Set the scale to “6 1 1 Manual with print key without stability”.

2. Just for testing purposes, start Simple Data Logger, press the Print/Menu key on the scale and confirm that the weight is shown in the event log in SDL (if not, please let me know).

3. Stop SDL, go to the control tab, enable the timer and enter the following (hexadecimal) command to be sent to your scale:

1B 50 0D 0A

(this is the escape character, “P”, carriage return and line feed as specified in the user manual).

4. Start SDL again. It should now send the command to your scale in the interval you chose and the scale should respond by sending the weight (just once for each command it received).

Hi Stephan,

It worked, thank you for inputs.I appreciate your efforts and immediate feedback.

Hi Mohmad,

Thank you very much for letting me know! We’ll add an “Acculab AL” device profile in the next release to make things easier to configure.

Hello.

This software seems very useful however I am having trouble getting data read out to my .csv file. I am using a Mettler Toledo NewClassic MS series load scale (MS4002S). I have the scale connected via USB (COM4) currently. I set up the program as suggested in the “How to Use Simple Data Logger” page. The first few times I tried to record data it would give me a single data point (when I hit “start”) – but always gave “4” so I’m not sure if this was actual data. When I did this I was using the default settings for the Mettler Toledo (MT-SICS) that are provided. After reading the FAQ I tried to change the interface settings to match this device (although I think they were already correct). Now my file does not give me any data at all, not even a start point. I am wondering if you have any suggestions on what to change in order to get data from the scale. I am attaching a few photos of the interface settings for my device, the event log when I try to record data, and my .csv file with the first 3 lines from the first 3 times I hit “record”.

Any suggestions are greatly appreciated!

Hi, as far as I can tell from reading the manual, you scale’s factory setting should work with SDL when using the MT-SICS profile. You should only have to change two settings in the menu of your scale:

USB – USB Interface: Set to “HOST” (not “PC-DIR”) and enable the interface by choosing “SEND.ALL” (or “SEND.STB”).

If everything is configured correctly, the weight received from your scale should show be shown in the event log (and be written to the CSV file). If not, please have a look at the possible causes listed here: https://www.smartlux.com/sdl/faq-support/#no-data

Thanks for the quick response!

An update: I found these settings and set to “SEND.ALL”. For some reason on the scale I cannot find the setting to switch from “PC-DIR” to “HOST”. (According to the manual it should be in between USB and SEND.__ settings but it just seems to be missing). Anyways, I now get values when I press a button on the scale (takes a measurement at that second), but not continuous data after pressing start.

Is this still an issue with the need for the scale to be set to “HOST”, or do I need to set up polling to get continuous data?

Does your scale have a “SEND.CONT” setting in the USB menu? This should send data continuously, though the manual does not say at which rate. If this doesn’t work, you can use polling in SDL instead. You can send us an email to request a trial license (to info@smartlux.com) or purchase our inexpensive 90 days license to try out this functionality: https://sites.fastspring.com/simpledatalogger/product/sdl90

The MT-SICS polling command can be set in SDL by pressing the “set default button” in the control tab: https://www.smartlux.com/sdl/documentation/#polling

Stephan,

Thanks again for the help. This works although it is at a weird rate (11 or 12 measurements per second). Polling would allow for this rate to be changed?

I think I will request a trial license and if this works certainly purchase a full license.

Yes, when using polling you can use a timer (or delay) to request the weight at a rate that suits your application:

https://www.smartlux.com/sdl/documentation/#polling

You’ll probably have to set your scale to “SEND.ALL” again to use this functionality. The default command defined in SDL should work if your scale is set to MT-SICS mode.

It’s possible that your scale also has an “interval” function which you could use instead of polling.

Hello. I am having some difficulties setting up SDL with and ADAM CBK8 set of scales. I have used the default settings for the CBK type but I find that when I plug the scales in then multiple MSWord documents are opened with no text in any of them and no data is captured by SDL. SDL finds two com port options and it happens in either. I have tried various combinations of continuous print, auto and manual modes with accumulate on and off. Any suggestions? Many Thanks

Adam CBK scales can be a bit difficult as they have many serial interface settings and the default values mentioned in the manual were often not correct in our experience. Please try using the following settings:

– if your scale does not have this setting, please let us know as you will have to make changes in SDL

Once you’ve made these settings, launch SDL, select “Adam CBK/GBK/GFK” as device and click on “set default parameters for device”. Then try using both COM ports one after another. As your scale is set to manual transmission, data should appear in the event log in SDL when you place something on the scale and press the print button.

Our software is not able to launch any other application like MS Word. It’s possible that your computer misidentified your scale as a serial mouse if it was set to continuous transmission. If that’s not the case, then maybe you’ve installed another data acquisition software which is launching Word?

Finally, please make sure you’re using the right cable. Adam CBK scales require a crossed serial cable (null modem), like this one: https://amzn.to/2TMBMxY

Thanks Stephan, much appreciated. Unfortunatley it’s still not working. I think the problem is with the serial cable connection. I dont have a serial port on my laptop so I am using an adaptor to plug into a USB port coupled with a gender changing adptor at the serial end so that I can plug it in. Is that likely to work?

Hi Dan, I think you’re right, the cable connection is causing the problem. The gender changer is equivalent to a straight (1:1) cable, but your scale requires a crossed (null modem) cable. You could use your USB adapter with a DE9F to DE9F null modem cable (like https://amzn.to/2TMBMxY) or buy a special USB adapter with null modem functionality already built in (like https://amzn.to/2JtF8kO). There are also tiny null modem adapters (https://amzn.to/2WdcqpO) but you would have to use those together with the gender changer (great for experimenting, but might not be the best solution for productive use).

Problem solved with the new cable! Thanks again Stephan.

Every time I try to use this, it connects easily to the scale, but it will not print the data into the CSV file. Instead, when I click “Stop” it says “Ignored Data” in the log and shows all of the weights that I entered in the scale. What am I doing wrong?

10:38:31: Logging to file: C:\Users\BetsysStaff\Documents\portion control 2.csv

10:38:31: Connecting to Generic measuring instrument on COM5

10:38:31: COM5 opened: 9600 bit/s, 8 data bits, 1 stop bit, parity none, flow control none, terminator 10, timeout none, DTR on, DSR on, RTS off, CTS on

10:40:47: Cancellation requested by user

10:40:47: Closing COM port

10:40:47: Closed

10:40:47: Ignored data: 4.85 oz 3.60 oz 4.95 oz 1.00 oz

This happens when SDL cannot find the terminator in the data sent by the scale. With your configuration, SDL expects to find the line feed character (ASCII code 10) after each weight value (which would then be processed and written to the CSV file), but it seems your scale does not use a terminator at all. Please try setting a timeout in the input tab (e.g. 100 ms) instead of a terminator: https://www.smartlux.com/sdl/documentation/#terminator

This solution worked great for a while, but since last month, the logger now records line after line of blank data when you hit “stop” which freezes it and prevents printing to file. It only works correctly when doing a small batch of data at a time.

Thank you for your feedback. Could you please let me know which version of SDL you’re using (version number is shown in the ‘about’ tab)?

Hi, Stephan! It is 1.3.2

Hi Ryan, you could try the following:

1. Update to the newest release 1.3.3 (https://www.smartlux.com/sdl/download/) or

2. as you said that SDL was previously working fine, uninstall the current version and downgrade to 1.2.1: https://www.simpledatalogger.com/publish/installer/Setup1-1-2-1.msi

Please let me know if one of these suggestions work. Thanks!

Dear Sirs.

I did use the product SDL, wery well.

I wonder if it is possible to overwrite the data of the file (csv or txt) instead of writing in a new line.

best regards

This is currently not possible. We’ll add an option to overwrite the file instead of appending data in a future release.

Really like the software, very simple and works perfectly the first time without even any changes to the generic device settings (used with a Prime Scales PS-IN202).

Only change I would ask is that the window scroll down while data is being gathered so you can see data real-time. That’s a big one actually because it makes troubleshooting so much simpler.

I hope you expand this software a bit to show a simple graph of the data and then an analysis screen with a simple drag bars to select areas of the graph to analyze with basic results of the sample area like peak, min, average, # samples, time, etc. Don’t get fancy (you’ll price yourself out of your market) but make it SIMPLE and just enough basics to be useful.

Thanks!

Thank you for your message! Auto scrolling is now available in version 0.4.8.